Align Bore & Balancing

Our align boring department provides a wide variety of services for our customers. With our Berco Align Boring machine we bore main lines for many diesel, industrial, agricultural, passenger car, and performance applications.

Connecting Rods & Pistons

Our rod department features two Sunnen rod honing machines, and two Kwik Way rod boring machines. Using these machines we can check or resize your connecting rods, as well as installing and fitting wrist-pin bushings, ranging from small engines to heavy duty diesel engines.

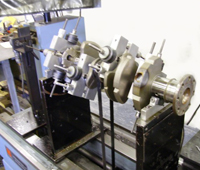

Crankshaft Grinding Department

Our crankshaft grinding department is the largest of its type in the Midwest. With an investment of over $500,000 and 6,000 square feet of work area, this department is comparable to no other in the area.

Cylinder Boring Department

Our cylinder and block re-manufacturing area consists of the most modern equipment available. Our three Kwik-way vertical boring mills and three Sunnen automatic cylinder hones guarantee block machining and cylinder sizes accurate to tenths of thousandths.

Cylinder Head Department

We are familiar with industrial, agricultural, marine, antique, small engine, and performance work and more. Our services include valve jobs, crack detection, leak detection, crack repair, injector tube replacement, valve seat replacement, valve guide replacement, head resurfacing, exhaust and intake resurfacing, broken bolt removal, and much more.

Monday-Friday: 8:00am - 5:00pm

Wednesday: 8:00am - 8:00pm

Saturday & Sunday: Closed